Loose Container Lashing Equipment

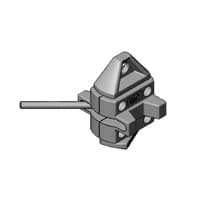

Base Stacking: Twist Locks

| Model | Weight kg | Dimensions mm | Min Breaking Load kN/Tn |

|---|---|---|---|

| CB-25-1G | 7,00 | 175 x 140 x 128 | 420 Tn |

| CB-25-1L | 7,00 | 176 x 140 x 129 | 420 Tn |

| CB-34-1L | 7,00 | 176 x 160 x 136 | 420 Tn |

MATERIAL: Ductile iron/Housing: Ductile Iron; Cone: Drop Forged FINISH: Hot Deep Galvanised

Loose Container Lashing Equipment

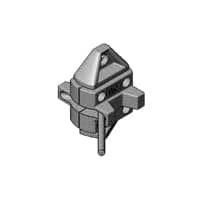

Intermediate Stacking: Container Twist Locks

| Model | Weight kg | Dimensions mm | Min Breaking Load kN/Tn |

|---|---|---|---|

| CI-5-1D | 5,00 | 120 x 100 x 172 | 500 kN |

| CI-5-1L | 5,00 | 120 x 100 x 172 | 500 kN |

| CI-21-1D | 6,00 | 145 x 113 x 169 | 300 kN |

| CI-21-1L | 6,00 | 145 x 113 x 169 | 300 kN |

| CI-15A-1 | 6,00 | 178 x 120 x 190 | 50 Tn, 500 Distance between containers |

| CI-45-1 | 7,00 | 163 x 120 x 224 | 50 Tn, 500 Distance between containers |

| CI-45-1G | 7,00 | 163 x 120 x 224 | 50 Tn, 500 Distance between containers |

MATERIAL: Housing: Ductile Iron; Cone: Drop Forged FINISH: Hot Deep Galvanized

What Is A Container Twist Lock?

What is a Container Twist Lock used for?

Twist locks and corner castings combined make a standard rotating connector used to secure shipping containers. Their main uses include locking a container in place on semi-trailer trucks, container trains, or container ships, and for lifting containers either by side lifters or container cranes. Developed by transport engineer Keith Tantlinger, twist locks aim to make the world of trade and transport easier and more efficient. Since it can take months before a container can be inspected again, the major advantage of this device is that it doesn’t need regular maintenance to function effectively. Even after being exposed to weather for a long time, a container twist lock makes a container as simple to move as ever. But, when corrosion is extensive (to the point it’s visible,) twist locks can degrade and make it dangerous to move the crate.

How Do Twist Locks Work?

The male part of a twist lock is fitted to vehicles and equipment and will normally work with any standard containers. It’s more exposed, too, making it more prone to damage. Meanwhile, the female part is called the corner casting, which has no moving parts. It has an oval hole in the bottom and is attached to the container itself.

The hole is roughly 5 inches long with two flat sides about 2 ½ inches apart. The male part of the container twist lock, which is fitted in bases and cranes, is inserted through the hole and usually has a pointed top portion to make insertion easier. It’s then rotated 90 degrees so it can’t be withdrawn. The maximum size and placements of holes in the corner castings are defined by international standards and the ultimate tensile strength of twist locks is rated at 20 or 25 tons.

Simpler versions of twist locks use tools for installing and removing them while modern versions already have built-in levers or mechanisms. Some twist locks can be installed permanently (i.e. on the beds of semi-trailers or on the deck of container ships) while some are installed temporarily so they can be easily removed when needed (i.e. to stack containers in storage yards.)

What is a Dovetail Container Twist Lock?

Dovetail twist locks are used in securing containers on the deck of a ship or any surface where you want to put the container. They’re used to safely and easily secure the bottom containers to hatch covers and in-holds where a raised socket can be seen as an obstruction. Our dovetail twist locks are made of forged steel with a hot-deep galvanized finish.

You’ll know the container is locked into place by looking at the handle’s direction. We suggest attaching one double-ended twist lock on all four corners of the shipping container.

These can be used with the dovetail foundation, too. Dovetail foundations (or dovetail plates) may be attached to the hold to reduce hazards and obstructions in the deck. The twist locks can then be slid in and out of the plate to make the surface area more versatile.

Guidelines When Using a Container Twist Lock

- Never use right-hand and left-hand twist locks on the same ship.

- Make sure to check all equipment, not just those used regularly, and always keep twist locks clean and well-greased.

- Check container corner castings regularly for signs of wear at the twist lock securing points. This is important, especially when using fully-automatic twist locks.

- Stow twist locks safely in their proper racks or baskets.

- Never use semi- and fully-automatic twist locks without checking the manufacturer’s instructions and the ship’s requirements in cargo securing.

- Avoid using twist locks that aren’t certified.

- Do not use twist locks for lifting containers except when they’re made especially for that purpose.

- Never walk or stand below containers that are being lifted since a container twist lock and other debris can sometimes fall.

- Avoid throwing or dropping twist locks or other fittings from a great height onto hard surfaces or a steel deck.

- Never use a combination of manual, semi-automatic, and fully-automatic twist locks in the same stowage.

- Make some clearance between the sliding socket and twist lock to allow the containers to move before the twist locks engage.

- A twist lock can be rated for various loads so make sure not to use a mix of twist locks made for different strength ratings.

- The castings should be the only points at which a container can be supported and where twist locks or other securing fittings may be attached.

- Since vertical tandem lifting is far more dangerous, you should only consider it if the container’s corner castings are also approved for lifting.

- Twist locks are enough to secure containers on deck given that the stack isn’t two levels high. When containers carried are three or more levels high, twist locks may still be used but it will still mostly depend on the weight of the containers. For loads more than three containers high, it’s better to attach lashing rods to provide additional strength.

Tec Container is an industry leader when it comes to shipments and cargoes. We offer a wide range of lashing equipment and accessories such as container twist locks to ensure the success of your freight-handling business.