Shore-to-ship power, also known as shore connection or cold ironing, is the process of generation and provision of shoreside electrical power to a ship while at berth. In this way the boat can disconnect the main engines and thus reduce pollution emissions, local noise and fuel consumption. Historically, the process of cooling the boilers of the coal engines when the ships arrive at a port is known as cold ironing. That term has been maintained to date. Nowadays cold ironing is a trend in the Green Shipping sector.

Once the cold ironing process is complete and the boat is connected, some systems such as ventilation, heating or cooling, pumps and load handling can be powered by this electrical energy coming from the coast without the need to connect the generators of the boat.

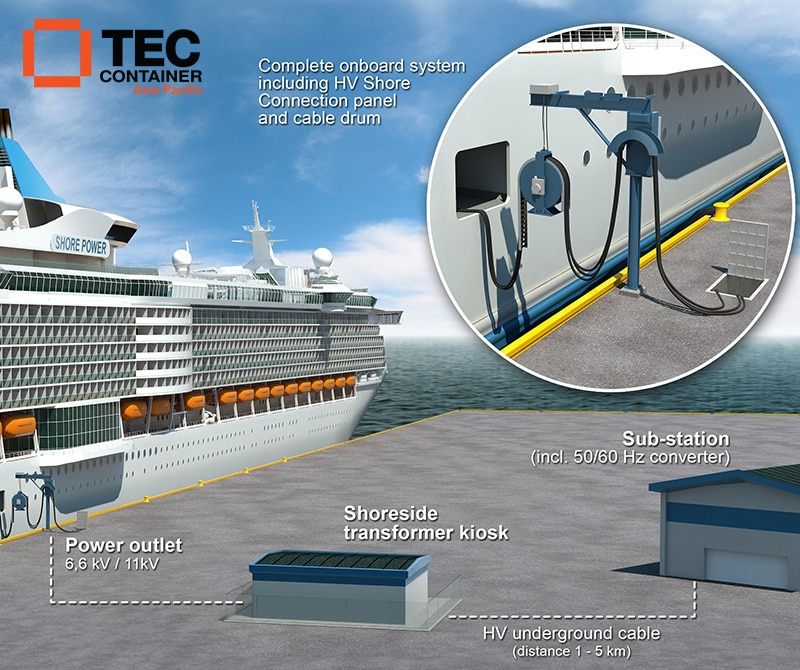

Requirements at the Port:

- High voltage grid at the port;

- Frequency and voltage convertors/transformers

- Control panels and connection boxes

- Cable reel and connectors

Requirements in the Vessel:

- Transformer

- Power distribution system

- Control panel

- Frequency converter (optional for greater flexibility)

- Connectors and cable reel (optional for greater flexibility)

Benefits for the maritime industry in the application of the Cold Ironing

- Drastic reduction of emissions while the vessels are at berth

- Drastic reduction of noise levels

- Better onboard comfort while in port;

- Green profile for ship owners and customers;

- Reduced lifecycle cost by fewer fuel consumption and maintenance cost.

The EU Directive 2014/94, about the implementation of an infrastructure for alternative fuels and shore power requires all major European ports to provide electricity from land, and the directive clearly indicates that Cold Ironing is seen as a step towards reducing emissions from shipping.

Main Challenges to be faced:

- Terminals need extra electrical capacity, conduits, and the ‘plug’ infrastructure, in order to accept power cables from a vessel. For example, a large container ship may need up to 1,600 kilowatts of power while at berth, but this power can vary significantly.

- Lack of standardization, which may lead to technical issues.

- Absence of concrete regulation.

For more information about cold ironing and other disruptive technologies in the Maritime Industry, call us at 1300 881 145 or contact our team below for more information: